UPDATES

Researchers synthesize a new 2D Metal Organic Framework with an ever-growing list of possible applications

Chemical vapor deposition (CVD) growth of graphene on metal substrates, especially on copper (Cu) foils, is an effective and popular technique to synthesize graphene approaching perfect crystallinity. Covalent chemical functionalization of defect-free (and thus the most chemically inert) graphene on Cu with deliberately chosen appending groups is not only fundamentally important for understanding its chemistry, but also for tailoring its structures and properties, and could be beneficial in practical uses such as for electrochemical sensors, optical devices, non-corroding current collectors, and as electrodes in electrical energy storage systems, among other reasons. The chemical reactivity of graphene on Cu foil substrates is a currently a topic of fundamental scientific study.

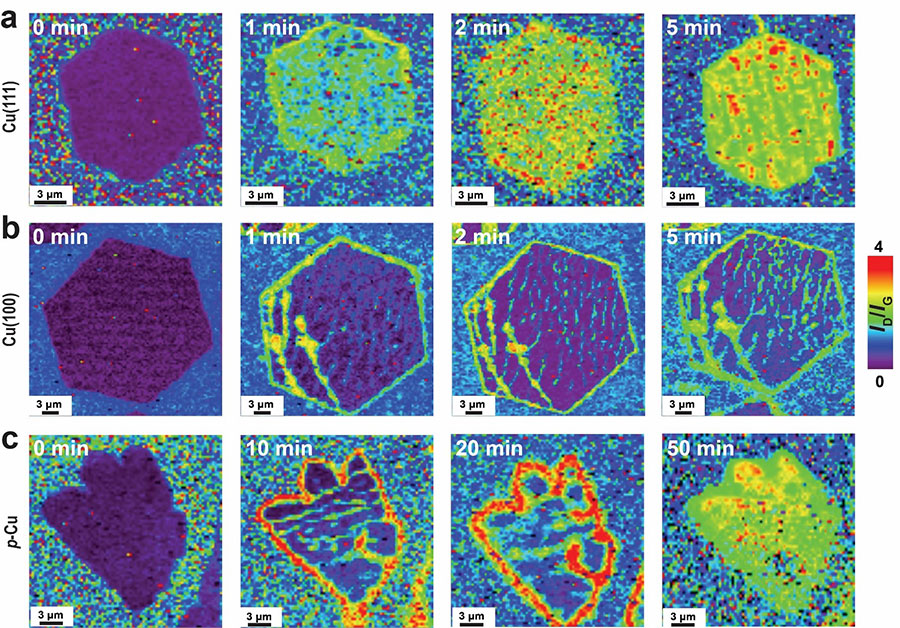

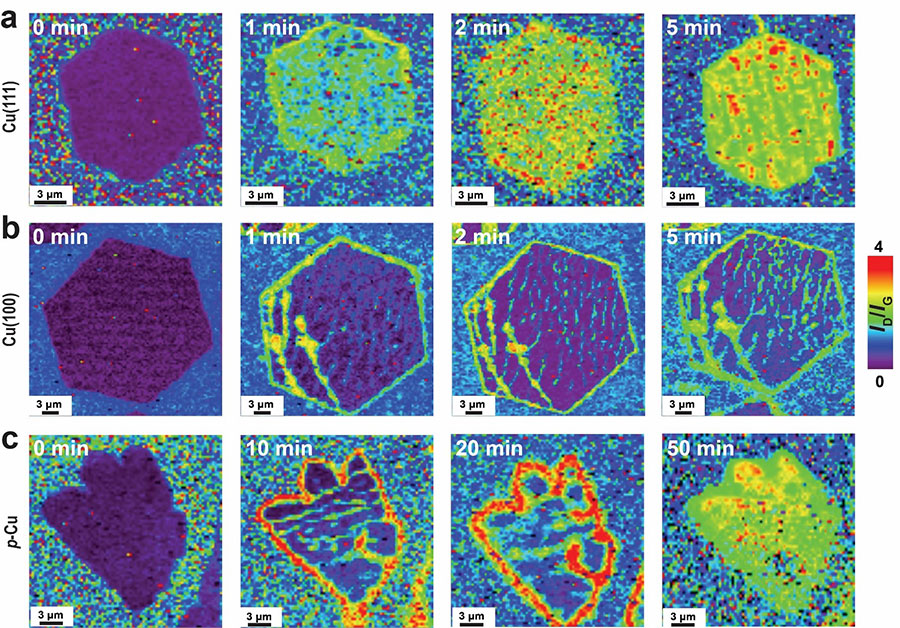

▲ Figure 1. The reaction behaviors and progression of chemical functionalization on graphene islands on single-crystal copper foil substrates (a and b) and on a polycrystalline copper foil substrate, as shown by sequential Raman spectroscopy ID/IG (height) maps over time. (a) Cu(111). (b) Cu(100). (c) Polycrystalline Cu.

To elucidate the reaction behaviors of graphene on Cu, the IBS research team led by Rodney S. Ruoff at the Center for Multidimensional Carbon Materials, who is also a Distinguished Professor at the Ulsan National Institute of Science and Technology (UNIST), along with Dr. Xu Zhang and coauthors, employed their newly-developed single-crystal graphenes on large-area Cu(111) and Cu(100) foils, as well as polycrystalline graphene grown on commercial polycrystalline Cu, to study some particular chemical reactions including a newly-developed reductive functionalization of graphene originally proposed by coauthor Prof. Christopher W. Bielawski.

They found that the reaction occurs much more readily on single-crystal graphene on Cu(111) such that uniform functionalization of single-crystal graphene islands, and separately of completely grown continuous single-crystal graphene films, could be obtained. The extent of reaction is even higher than for graphene transferred onto silicon wafers having an oxide layer, a well-studied platform with relatively high reactivities. In contrast, graphene islands and continuous films grown on Cu(100) and polycrystalline Cu foils reacted to a much smaller extent. It was learned in the study that the size of the graphene islands on the Cu(111) has no influence on the functionalization, as further demonstrated by the similar efficiency of functionalization for continuous single-layer graphene films on Cu(111); this strongly implies that the reaction selectively takes place on the topside of graphene.

Based on a series of Raman spectroscopy studies along with other experimental techniques and theoretical calculations, the noticeable strong difference of graphene’s reactivity on Cu substrates of different surface crystal orientations is because the graphene is under compressive strain that is significantly larger (its biaxial strain is about 0.3%) on Cu(111) owing to lattice-induced friction between the epitaxial graphene and Cu(111). Such a friction, previously presented by collaborator Prof. Feng Ding, leader of the IBS CMCM Theory Group, is much smaller for graphene on other surface-oriented Cu foils, in which compressive strain is largely released (it is less than < 0.1%) by local deadhesion (the friction is too small!) and thus “graphene wrinkles” are formed.

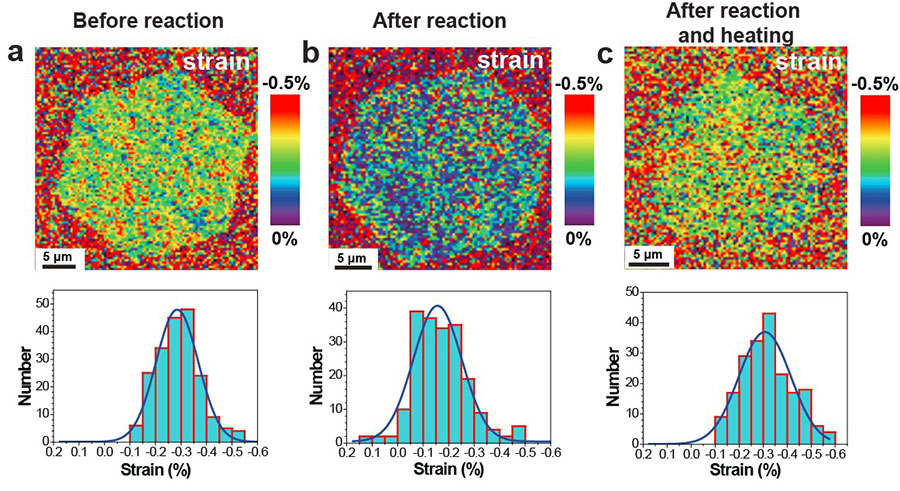

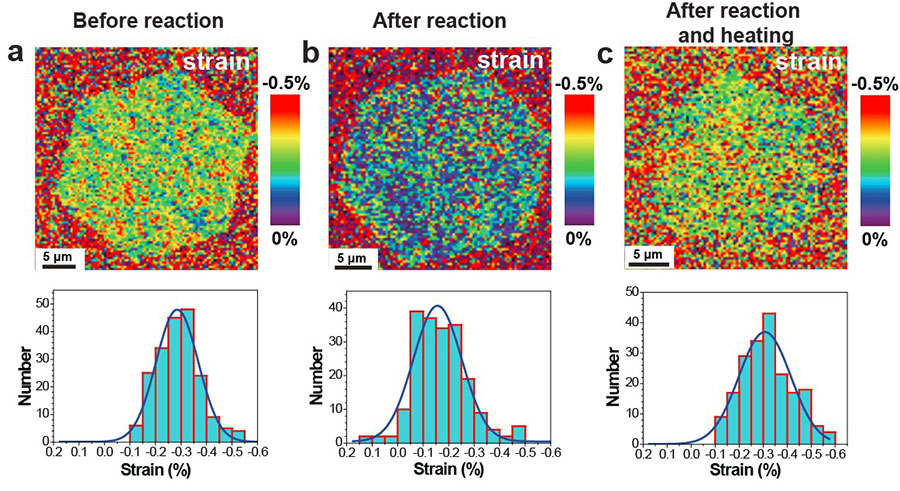

▲ Figure 2. Spatial and statistical analyses of compressive strain for typical graphene islands on Cu(111) after different treatments. (a) Strain map of a pristine island. (b) Strain map of a reacted island. (c) Strain map of an island after functionalization followed by thermally driven defunctionalization in Ar.

It was learned that the compressive strain present in the single-crystal graphene on the Cu(111) foil substrate could be changed by chemical reactions with the surface. Covalent functionalization was found to “relax” this compressive strain, and then when the functional groups were eliminated from the graphene by heating, the compressive strain was largely recovered. Since strain determines diverse physical properties of materials, this unique approach to “strain engineering” may be useful for particular types of graphene-based devices.

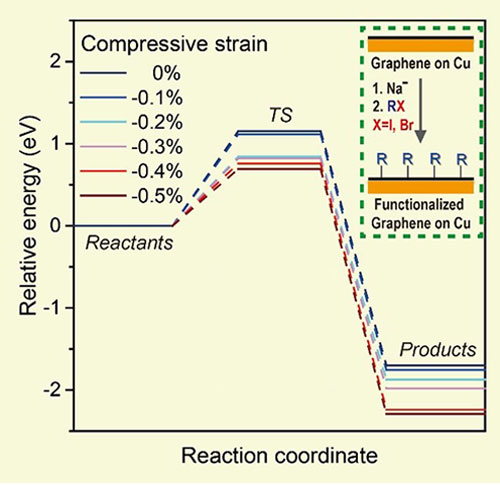

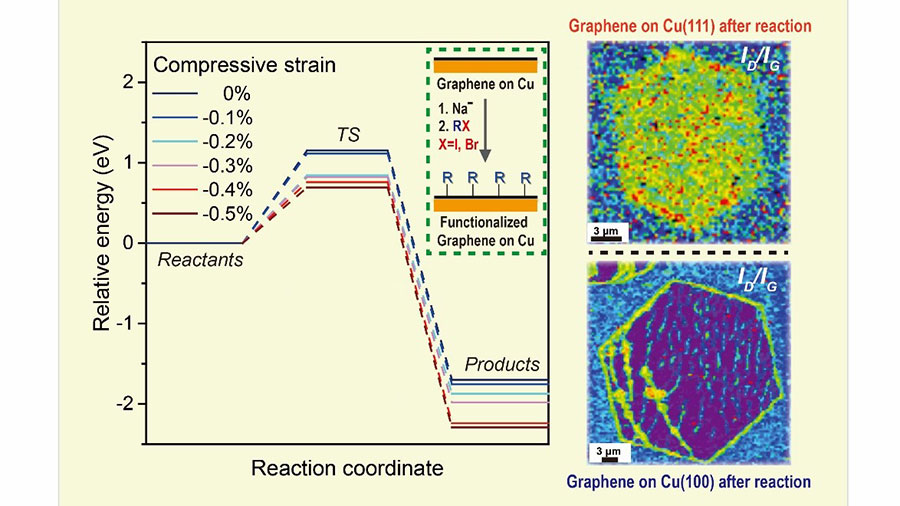

▲ Figure 3. The influence of compressive strain, which is alterable by the surface orientation of Cu, on the reactivity of graphene on Cu in a reductive functionalization. Note that the minus sign “-” means compression (“+” for tension).

The influence of compressive strain on the energy barrier of graphene on Cu was investigated by theoretical calculations performed by Prof. Sang Kyu Kwak and his team members Mr. Dae Yeon Hwang and Mr. Sung O Park. The results showed that compressive strain was critical in lowering the energy barrier of the reactions. When the compressive strain was higher than 0.2%, the energy barrier for chemical reaction was reduced by around 0.3 eV. Study of the reaction kinetics of this chemical reaction on this single-crystal graphene on Cu(111) yielded a relatively low activation energy of around 20 kJ∙mol−1, a value favoring the spontaneous reaction at room temperature—a spontaneous reaction driven by release of this compressive strain.

The scientists also investigated the covalent functionalization of bilayer graphene on Cu(111). The reactivity of bilayer graphene is influenced by the stacking mode of the two graphene layers. “Mis-oriented graphene” is more easily functionalized than graphene with no lattice rotation (“AB-stacked”). The team learned that the mis-oriented bilayer graphene also has a higher compressive strain than AB-stacked bilayer graphene, suggesting that the compressive strain may also influence the reactivity of bilayer graphene.

Director Ruoff said, “For some applications, large-area single-crystal graphene, which can now be readily grown on our large-area Cu(111) foils, is likely superior to polycrystalline graphene grown on polycrystalline Cu foils. Our findings about the effect of Cu surface orientation on the covalent chemistry of graphene sheds light on the fundamental chemistry of single-crystal graphene and the role that compressive strain can play in some reactions, which could find many applications; one reason that this might be immediately useful, is that the continuous single-crystal graphene films are “automatically” under compressive strain when removed from the CVD growth chamber—and that compressive stress at the interface between the single crystal copper surface and the single crystal graphene—provides a chemical driving force for reacting the top surface—the exposed surface—of the graphene.” This research was supported by the Institute for Basic Science and has been published in the journal Chemistry of Materials: https://pubs.acs.org/doi/10.1021/acs.chemmater.9b01729

- IBS 연구진, 그래핀 기능화 반응 촉진하는 새 방법 규명 -

기초과학연구원(IBS, 원장 대행 김영덕) 다차원 탄소재료 연구단 로드니 루오프 단장(UNIST 자연과학부 특훈교수) 연구팀은 울산과학기술원(UNIST)과 공동으로 스트레스1)가 그래핀에 기능기2)를 더하는 반응을 촉진시킨다는 연구결과를 발표했다.

탄소가 육각형 벌집 구조로 이어진 얇은 탄소막인 그래핀은 우수한 물리적·화학적 성질 덕분에 차세대 소재로 각광받는다. 더 나아가 그래핀에 각종 기능기를 추가(기능화 반응)하면 물리화학적 성질을 변화시켜 다재다능한 소재로 만들 수도 있다. 하지만 아직까지 그래핀의 기능화 반응을 촉진하는 명확한 메커니즘은 밝혀지지 않았다.

연구진은 그래핀 합성에 주로 사용되는 구리 기판의 표면 결정구조가 기능화반응에 영향을 준다는 사실을 밝혀냈다. 결정구조는 기판을 구성하는 구리 원자들이 배열한 형태를 말한다. 결정구조가 같더라도 단면의 방향에 따라 표면의 결정구조가 달라진다. 수박을 가로로 잘랐을 때와 세로로 잘랐을 때 표면이 다른 것과 마찬가지로, 똑같은 구리라도 결정구조 단면에 따라 구리(001), 구리(110), 구리(111) 등으로 구분된다.

연구진은 결정구조가 다른 세 종류의 구리 기판 위에서 그래핀의 기능화반응을 진행했다. 그 결과 구리(111)를 기판으로 사용했을 때가 가장 기능화 반응이 빠르고 균일하게 진행됨을 확인했다. 그 이유는 구리(111) 표면에서 성장한 그래핀이 가장 스트레스를 많이 받기 때문인 것으로 분석됐다.

연구진은 합성과정에서 그래핀이 스트레스를 받으면 압축변형이 잘 일어나고, 압축변형률이 클수록 반응에 필요한 추가 에너지가 적어지기 때문에 반응이 더 쉽게 일어나는 것이라고 설명했다. 구리 기판 위에서 스트레스를 받으며 성장했지만, 기능화 반응에서는 스트레스의 덕을 본다는 의미다. 한편, 열을 가해 기능기를 제거했을 때는 그래핀의 압축변형률이 원래대로 돌아오는 현상도 확인했다.

루오프 단장은 “단결정 그래핀에서 스트레스로 인한 압축변형이 그래핀의 반응성에 영향을 준다는 점을 규명한 뜻깊은 연구”라며 “이번에 발견한 원리를 이용하면 기존보다 쉽게 그래핀의 성질을 조절해, 다양한 기능성을 갖춘 그래핀을 제조할 수 있다”고 말했다.

이번 연구결과는 재료화학분야 국제 학술지인 ‘케미스트리 오브 머터리얼스(Chemistry of Materials)’ 10월 17일자 온라인 판에 실렸다.

▲ [그림 1] 구리 기판 표면의 결정구조에 따른 반응성 분석

라만분광법을 이용해 3가지(단결정 구리(111), 단결정 구리(100), 다결정) 표면 결정구조를 갖는 기판 위에서 그래핀의 기능화 반응을 비교했다. 단결정 Cu(111) 표면(최상단)에서 가장 빠르고 균일하게 반응이 일어났다.(색상변화)

▲ [그림 2] 기능화 반응과 열처리가 그래핀의 압축변형(strain)에 미치는 영향

기능화 반응 전(a)과 기능화 반응 후(b)를 비교했을 때, 기능화 반응 후의 변형률이 낮아짐을 볼 수 있다. 또 열처리를 통해 기능기를 제거하면(c) 변형률이 반응 전과 유사한 수준으로 돌아온다.

▲ [그림 3] 압축변형률(strain rate)이 그래핀의 환원 기능화 반응 에너지에 미치는 영향

압축변형률이 높을수록(압축변형률이므로 ‘–’절대값이 클수록) 환원 기능화 반응에 필요한 에너지가 낮아진다.